Safety Moment #75: Pressure Tests

After a piece of equipment or piping that operates under pressure has been opened and then reassembled (buttoned up) it must be pressure tested before being put back into service.

Safety Moment #76: Plugged Process Piping

Process lines, piping and valves frequently become plugged. If line pluggage is a recurring problem it is best to try and identify ways in which the problem can be prevented from occurring. If that solution is not possible then valves, drains, tees and connections should be designed so that it is possible to remove the pluggage safely and with minimum time and expense.

Safety Moment #73: Storage Tanks in the Process and Energy Industries

September 2022

OSHA has opened the Process Safety standard for comment and revision. One of the items on their list is to do with storage tanks. Item II.1 reads,

Clarifying the exemption for atmospheric storage tanks

Safety Moment #66: The Most Important PSM Elements — Participation

In an earlier Safety Moment we saw that the term ‘Process Safety Management’ (PSM) can become diluted to the point where it loses any meaning. This is unfortunate. The term is not just another way of describing industrial safety — it has a tight and specific significance, as explained in Process Safety Management. The description discusses the three words that make up the term: ‘Process’, ‘Safety’ and ‘Management’, and how they should be applied.

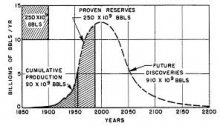

The New PSM Normal (3) — Peak Oil

This post is the third in a series in which we consider how our approach to industrial safety, and process safety in particular, may change in response to the COVID-19 pandemic. It is early days — no one knows what the ultimate health and economic effects of this frightening event will be. But it seems likely that we are entering a ‘New Normal’. So much has happened so quickly that it is hard to visualize how we can return to the ‘Old Normal’. All of us wish for a quick, V-shaped recession, after which the economy comes roaring back, more vibrant than ever.

Safety Moment #65: Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is the last line of defense for keeping a person safe. Every effort should be made to protect the wearer ahead of time. The Irish Health & Safety Authority provides the following precautionary statements with regard to PPE.

Safety Moment #87: Hydrogen Sulfide

Hydrogen Sulfide

Hydrogen Sulfide is a highly toxic chemical compound that is found in a wide variety of oil processing operations. High concentrations of H2S may be present in crude oil, molten sulfur, tank and pit-bottom sludge and produced water, all of which may release H2S when agitated, heated, or depressurized. Typical operational activities where personnel may be exposed to H2S include drawing samples, handling and testing samples, gauging tanks, and when opening lines and equipment.

Safety Moment #54: The Process Safety Professional

The contents of this Safety Moment have moved to The Process Safety Professional.