Lowest Level of Risk (BSEE)

Overview (BSEE Risk)

As part of its Well Control Rule BSEE appears to have made a major change in the manner in which offshore risk is to be managed. Section 250.107(a)(3) states,

[y]ou must protect health, safety, property and the environment by utilizing recognized engineering practices that reduce risks to the lowest level practicable when conducting design, fabrication, installation, operation, inspection, repair, and maintenance activities.

Event Tree Analysis

Overview

Event Tree Analysis (ETA) uses the same logical and mathematical techniques as Fault Tree Analysis. However, whereas a fault tree analyzes how an undesirable top event may occur, an event tree considers the impact of the failure of a particular component or item in the system, and works out the effect such a failure will have on the overall system risk or reliability. Event trees use an inductive approach, whereas fault trees are deductive. Event trees were developed for the nuclear industry. They are much less widely used in the process industries.

Safety and Environmental Management Systems (SEMS)

History of Safety Management in the Process Industries

Video

History Safety Management: we have published a 30 minute video package that shows how safety management systems in the process and energy industries have developed during the course of the last 300 years. The YouTube video shown at the end of this page provides a short extract.

Standard Examples

We have developed a set of process safety management standard examples that are used to illustrate some of the concepts and ideas developed in our publications.

Example 1 - Facility Design

A process consists of four operating units and a utilities section. A schematic of the system is shown in Figure 1.

Flammable and Combustible Materials

The material in this article is extracted from Chapter 1 of the 2nd edition of the book Plant Design and Operations and in the ebook 52 Process Safety Moments.

Fault Tree Analysis

The content of this Article has been moved to Safety Moment #94: Fault Tree Analysis.

Pig Launching and Retrieving

This article provides guidance to do with the launching and retrieving of pipeline pigs (also known as scrapers or tools).

Pig Launching

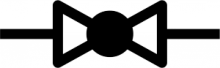

Below is a schematic of a launcher.

Equipment Isolation Methods

Isolation Methods

Positive isolation methods are those which remain effective even if there is equipment failure or operator error. These techniques apply not only to vessels, piping and tanks but also to pneumatic and hydraulic equipment.

The sketch shows some of the various isolation techniques that can be used to protect workers in the process industries. The process containing toxic or flammable chemicals under pressure is on the left; the open system, where the workers are present, is on the right. The order is from the least to the most secure.